Drive belts and V belts serve the crucial function of transferring power in machinery systems. Drive belts, typically made of rubber or a similar material, connect two or more rotating shafts. They are commonly used in applications where a smooth transfer of power is required. V belts, on the other hand, are named for their trapezoidal cross-section, which allows them to grip the pulleys more effectively. This design feature makes V belts ideal for high-torque, low-speed applications. Both types of belts must be properly maintained to ensure optimal performance and prevent breakdowns. Regular inspection for wear and tension adjustment are key aspects of belt maintenance to keep machinery running smoothly.

Definition and Types

Drive belts and V belts, integral components in mechanical systems, transmit power between pulleys with efficiency and precision. They're crafted from a variety of materials, each selected for its durability, flexibility, and heat resistance. The material composition often includes rubber, neoprene, and polyurethane, among others, catering to the specific needs of the application. This choice in material directly influences the belt's performance, lifespan, and maintenance requirements.

Belt tensioning is another critical aspect, demanding precise adjustment to maintain best performance. Incorrect tensioning can lead to increased wear, reduced power transmission efficiency, and potential system failure. You've got to make sure that the tension is neither too high, causing excessive wear on the belts and pulleys, nor too low, resulting in slippage and loss of transmitted power. The correct tension is achieved through careful measurement and adjustment, typically following the manufacturer's specifications. It's a delicate balance, but getting it right guarantees the longevity and efficiency of the belt-driven system.

Key Differences

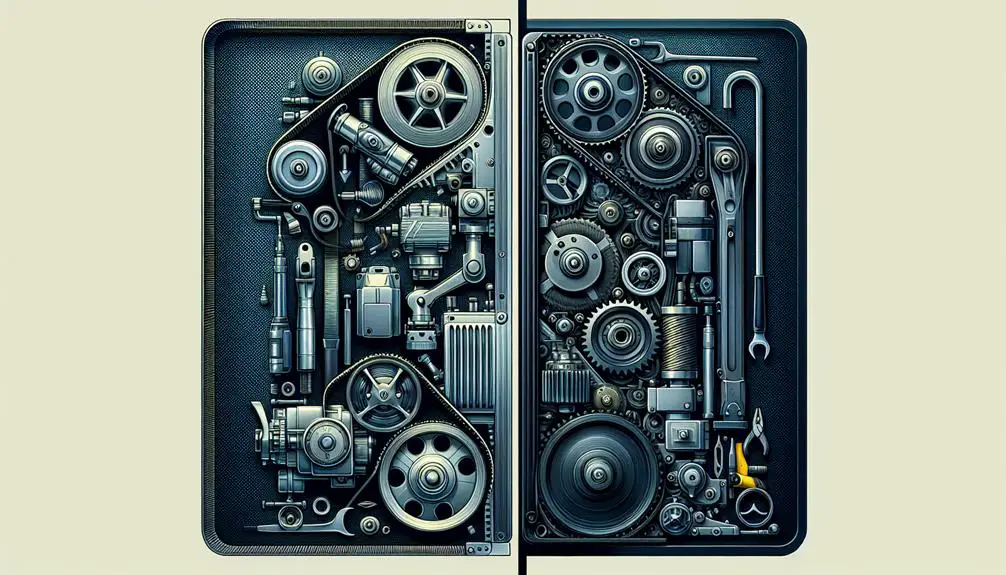

Grasping the key differences between drive belts and V belts is critical in selecting the best component for your mechanical system. The distinctions largely hinge on material composition and installation complexity, among other factors. Here's a closer look to guide your decision.

| Feature | Drive Belt | V Belt |

|---|---|---|

| Material Composition | Often made from rubber, neoprene, or polyurethane, incorporating fibers for strength. | Primarily constructed from rubber or synthetic rubber, with a unique V-shaped cross-section. |

| Installation Complexity | Tends to be more straightforward essential their flexibility and the variety of systems they fit. | Can be more complex, requiring precise alignment to match the pulley grooves. |

| Design Flexibility | Broad design options to suit a wide range of applications, including flat, ribbed, and synchronous types. | More standardized in design, focusing on efficient power transmission in specific pulley systems. |

Understanding these key differences is crucial you're well-equipped to make an informed choice. While drive belts offer versatility and ease of installation, V belts are recognized for their specialized application ensuring snug fit and alignment. Your selection should, therefore, reflect the specific requirements of your mechanical system, considering both material composition and installation complexity.

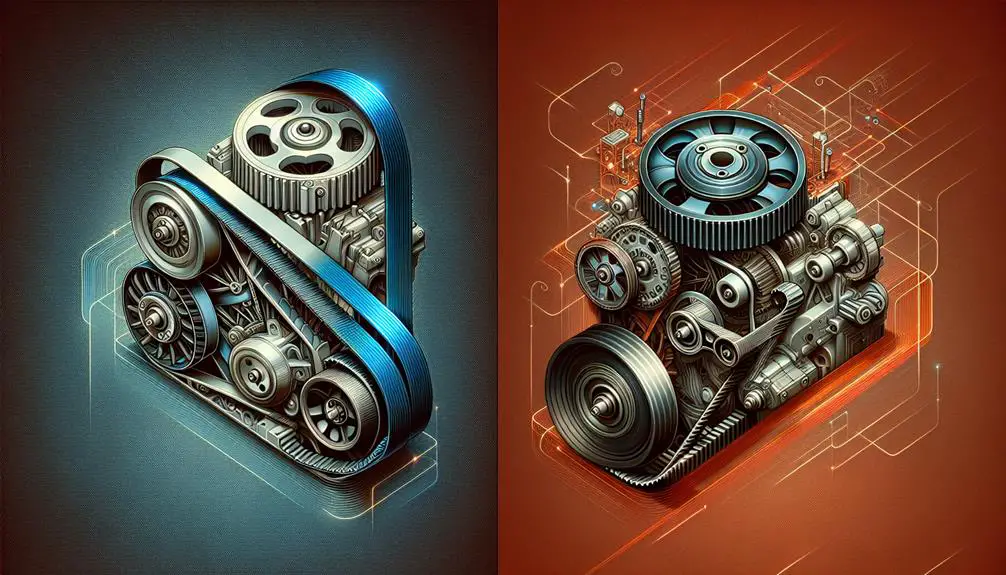

Performance and Efficiency

When evaluating the performance and efficiency of mechanical systems, it's critical to contemplate how drive belts and V belts directly influence power transmission and operational smoothness. You'll find that drive belts, with their flat surface design, often excel at minimizing slippage. This feature guarantees a more consistent transmission of power, which, as a result, can lead to improved efficiency of the machinery. The reduced slippage attribute of drive belts also plays a vital role in lowering noise levels, making them an ideal choice for environments where operational quietness is paramount.

On the other hand, V belts, with their unique cross-sectional shape, offer superior grip, which reduces the chance of belt misalignment and contributes to a smoother operation. Their design allows for excellent heat resistance, ensuring that they maintain performance even under high temperature, which is a critical factor for applications involving heavy loads or high speeds. This heat resistance capability of V belts not only extends their lifespan but also preserves the efficiency of the system by preventing the overheating that can lead to power loss.

Both types of belts have their merits regarding performance and efficiency, heavily influenced by their heat resistance and noise level attributes.

Application Areas

Comprehending the varied applications of drive belts and V belts is pivotal for optimizing mechanical systems for specific operational needs. It's essential to take into account both material compatibility and installation challenges when selecting the right belt for your application.

Drive belts, with their broader surface area, are ideal for high-power transmissions. They're especially suited for applications requiring smooth operation and minimal vibration, such as in automotive engines and heavy machinery. The choice of material is vital here; for instance, rubber drive belts offer flexibility and durability but may not be compatible with certain chemicals or extreme temperatures.

V belts, on the other hand, are designed for compact, high-speed applications. Their unique V-shaped profile ensures better grip and stability, making them a go-to for HVAC systems and agricultural machinery. However, their installation can be more challenging, requiring precise alignment to prevent uneven wear and tear.

- Material compatibility: Guarantees the belt's longevity and efficiency in specific environments.

- Installation challenges: Proper alignment and tension are crucial for the best performance.

- Operational needs: Whether it's high power or high speed, choosing the right belt can have a significant impact on system efficiency.

Maintenance and Lifespan

Appreciating the specific applications of drive belts and V belts sets the stage for discussing their maintenance needs and expected lifespan, which are key to ensuring peak performance and durability in mechanical systems. You must consider weather effects on both types of belts, as extreme temperatures and humidity can accelerate wear and tear. For drive belts, maintaining the best tension is critical; too tight, and you risk premature bearing failure, too loose, and you'll face slippage or reduced power transmission efficiency. Regular inspection for cracks, fraying, or glazing is also vital.

For V belts, proper alignment and tensioning during installation are paramount to prevent uneven wear and extend their service life. Installation tips include using a tension gauge to guarantee the correct tension and checking pulley alignment with a straight edge or laser aligner. It's vital to replace V belts in matched sets to avoid uneven load distribution.

Both belt types benefit from periodic cleaning to remove debris that can abrade the belt material. Adhering to these maintenance guidelines, you can typically expect a drive belt to last 3-5 years, while a V belt might last 5-7 years, depending on its application and environmental conditions.

Conclusion

To sum up, while both drive belts and V-belts play crucial roles in mechanical systems, they differ greatly in design, efficiency, and application specificity.

Drive belts, covering a wider category, excel in versatile applications, offering superior flexibility and load capacity.

Conversely, V-belts, with their unique trapezoidal shape, provide a cost-effective solution with remarkable precision in power transmission.

Best performance depends on choosing the right belt type, considering the specific mechanical requirements and operational conditions, ensuring longevity and minimizing maintenance demands.