Replacing points and condenser involves several steps:

- Removing old components

- Selecting new ones

- Installing the new components

- Fine-tuning for optimal performance.

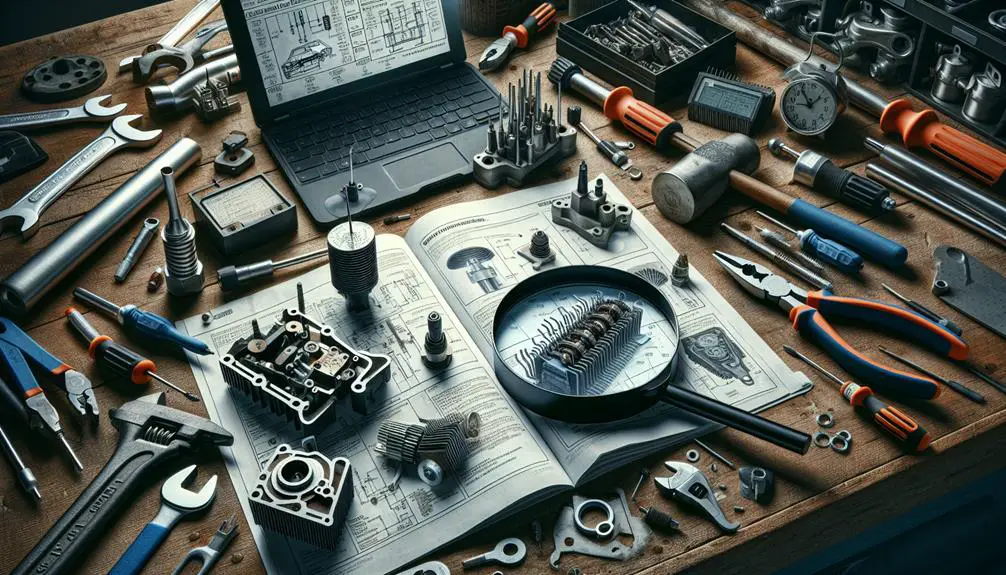

Preparing Your Workspace

Before beginning the process of replacing points and condenser, it's vital to prepare your workspace by ensuring it's clean, well-lit, and equipped with the necessary tools. A clutter-free environment not only helps ease of movement but also minimizes the risk of losing small, essential components. Start by clearing the workspace of any unrelated materials and wiping down surfaces to prevent dirt or debris from interfering with the components you'll be handling.

Workspace lighting is paramount; adequate illumination helps you spot small markings and subtleties on the points and condenser, preventing mistakes. If your primary light source isn't sufficient, consider adding a task light or a portable lamp that you can adjust to illuminate your work area directly.

Tool organization plays a vital role in the efficiency and safety of your work. Lay out your tools beforehand, ensuring they're within easy reach but not cluttering your workspace. Use a tool organizer or a magnetic tray to keep small tools and screws from getting lost. This systematic approach not only speeds up the process but also reduces the chances of errors or accidents.

Removing Old Components

After preparing your workspace, the next step involves carefully removing the old points and condenser from your ignition system. Begin by making sure the engine's lubrication system isn't compromised during the process. Disconnecting the battery should be your initial action to prevent any electrical hazards, thereby guaranteeing safe battery maintenance.

To proceed, locate the distributor cap and gently remove it. You'll find the points and condenser underneath. Using a screwdriver, unscrew the points from their mounting, making sure not to disturb the engine's timing settings. The condenser's removal follows a similar process; however, take extra care not to damage any adjacent wiring.

During this process, keep in mind the importance of keeping the components organized for a smoother reassembly. Below is a table highlighting key considerations during removal:

| Step | Tool Required | Key Consideration |

|---|---|---|

| Disconnect battery | – | Ensures safety |

| Remove distributor cap | Screwdriver | Prevent damage |

| Unmount points | Screwdriver | Preserve timing |

| Remove condenser | Screwdriver | Avoid wire damage |

| Organize parts | – | Facilitates reassembly |

Following these steps and considerations guarantees a safe and efficient removal of the old points and condenser, setting a solid foundation for the installation of new components.

Selecting Replacement Parts

Once you've removed the old points and condenser, it's significant to choose high-quality replacements to guarantee top performance of your ignition system. You'll need to pay close attention to compatibility issues and budget considerations during your selection process. Start by consulting your vehicle's manual or a trusted online database to identify the specific models compatible with your engine. Compatibility is important; mismatched parts can lead to poor performance or even damage to your ignition system.

Budget considerations also play a significant role in selecting replacement parts. While it's tempting to opt for the cheapest available options, bear in mind that quality often correlates with price in automotive parts. Investing in reputable brands can save you money and headaches in the long run by reducing the likelihood of premature failure.

When evaluating potential replacements, examine the specifications of each part carefully. Look for materials and construction that promise durability and longevity. Additionally, check if the manufacturer offers any warranties or guarantees, as these can provide added value and peace of mind.

Selecting the right points and condenser is a balance of compatibility, quality, and budget. Making informed decisions at this stage ensures the reliability and efficiency of your ignition system for miles to come.

Installing New Points and Condenser

Installing new points and condenser in your ignition system requires precise alignment and careful handling to guarantee peak performance. Taking the necessary safety precautions is vital before you start. Make certain the engine is off and the ignition key is removed to avoid any accidental starts. It's advisable to wear protective gloves to safeguard against cuts or electrical shocks.

Before installing, it's vital to:

- Clean the mounting surface thoroughly to ensure a good electrical connection.

- Apply a thin layer of lubricant on the cam where the points will ride. This reduces wear and extends the life of the points. Be sure to use the correct type of lubrication recommended for your vehicle.

- Position the new points carefully, making sure they're aligned correctly. The points should open and close smoothly without binding.

- Install the new condenser, making sure its lead wire doesn't interfere with any moving parts and is routed away from high-temperature areas.

After installation, double-check all connections to make sure they're secure and free of corrosion. This step is vital for maintaining the reliability of your ignition system. Remember, attention to detail during installation can have a significant impact on the performance and longevity of your points and condenser.

Testing and Fine-Tuning

Having installed your new points and condenser, it's time to test and fine-tune them to guarantee peak engine performance. You'll initially want to check the spark gap. This important adjustment affects how your engine ignites fuel. Using a feeler gauge, make sure the gap meets your vehicle's specifications. Next, focus on the ignition timing. This step is essential for your engine to run smoothly.

| Step | Emotion Evoked |

|---|---|

| Check Spark Gap | Anticipation |

| Adjust Ignition Timing | Satisfaction |

| Test Start Engine | Excitement |

| Fine-Tune for Performance | Pride |

To adjust the ignition timing, you'll need a timing light. Connect it according to the manufacturer's instructions. With the engine running, aim the timing light at the timing marks on the engine's crankshaft pulley. Adjust the distributor until the timing mark aligns with the correct specification.

After these adjustments, start the engine. It should fire up more readily than before, a proof of your precise work. To wrap up, fine-tune the settings under different loads to ensure top performance. Listen to the engine; it should run smoothly, without hesitation or misfires. Your technical prowess has directly translated into a more responsive and efficient engine.

Conclusion

Now that you've replaced the points and condenser, make sure everything's properly aligned and tightened.

Double-check the gap settings against the manufacturer's specs for precision.

Reattach the distributor cap and reconnect the battery.

Start the engine and observe its running; it should be smoother if everything's done correctly.

To fine-tune the ignition timing for best performance, use a timing light.

This meticulous approach guarantees your vehicle's ignition system operates at its peak, enhancing complete efficiency and reliability.