- Blown fuses and relays

- Faulty wiring connections

- A worn-out blower motor

- Resistor failure

- Clogged or dirty filters

These issues can cause a blower motor to stop working.

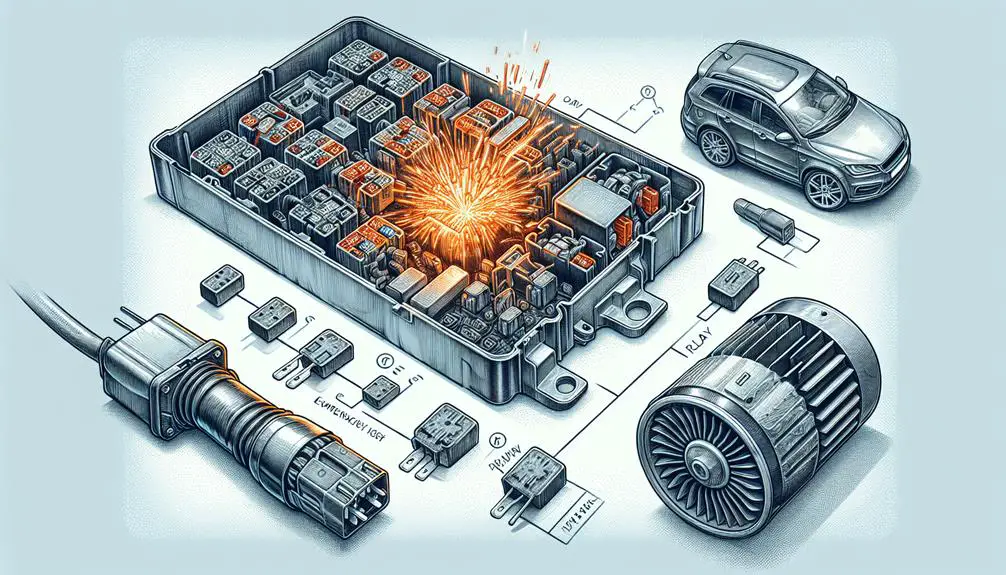

Blown Fuses and Relays

Often, the initial sign of trouble with your blower motor starts with blown fuses and relays failing to do their job. These components are essential for the proper operation of your blower motor, acting as safeguards against electrical issues. When they blow or fail, it's usually a warning that there's an underlying problem needing your immediate attention.

You're likely to initially notice something's amiss when your vehicle's HVAC system doesn't respond as expected. Maybe the air isn't blowing at all, or the system only works on certain settings. This inconsistency can be frustrating, especially in extreme weather conditions when you rely heavily on your vehicle's climate control.

Blown fuses are often a symptom of an overcurrent situation. This means something in the electrical system is drawing more power than it should, causing the fuse to blow to prevent damage. Identifying the cause of this overcurrent is key to preventing future issues. On the other hand, when relays fail, it's typically because of wear and tear or poor quality. These relays act as switches, and if they're not working, power can't reach the blower motor, rendering it inoperative.

Addressing these issues involves checking the fuse box and relay panel, usually found under the dashboard or in the engine compartment. Replacing a blown fuse might get your system up and running temporarily, but remember, it's a sign of a deeper issue. Identifying and fixing the root cause guarantees your blower motor works reliably, keeping you comfortable no matter the weather.

Faulty Wiring Connections

Faulty wiring connections can disrupt your blower motor's performance, leading to unexpected system failures. When you're dealing with a malfunctioning blower motor, it's important to check if the issue stems from poor wiring connections. Over time, vibrations, heat, and general wear and tear can loosen or damage these connections, interrupting the electrical flow. This interruption mightn't only cause your blower motor to stop working but can lead to intermittent operation, making it seem like the motor is on its last legs when, in reality, it's a simpler fix.

You'll want to inspect all wiring harnesses and connectors related to the blower motor circuit. Look for any signs of corrosion, frayed wires, or loose connections that could be causing trouble. Corrosion, in particular, can prevent electricity from flowing smoothly, acting as an insulator rather than a conductor. If you spot any damaged wires, it's usually best to replace them rather than attempting a temporary fix. Likewise, cleaning and securing any loose connections can restore your blower motor's functionality without the need for more extensive repairs.

Worn Out Blower Motor

After addressing wiring issues, another common cause for concern is a worn-out blower motor that has reached the end of its lifespan. When you're facing inconsistent airflow or no air coming from your vehicle's vents, it's possible that you're dealing with a blower motor that's simply had its day. Over time, the continuous operation can lead to wear and tear that's beyond repair. Recognizing the signs of a worn-out blower motor can save you from discomfort and potentially more significant issues down the line.

- Unusual noises: Imagine the whirring, squealing, or rattling sounds that become the unwanted soundtrack of your drives.

- Weak airflow: Picture turning on your AC or heater, expecting a gust of air, but only receiving a weak trickle, barely noticeable against your skin.

- Intermittent operation: Visualize the frustration as your blower motor decides to work on its schedule, unpredictably starting and stopping, leaving you at the mercy of its whims.

Comprehending these signs and responding promptly can prevent you from getting stuck in extreme weather conditions without a functioning HVAC system. If you suspect your blower motor is worn out, it's best to consult with a professional who can accurately diagnose and replace the motor if necessary.

Resistor Failure

Another significant aspect to contemplate is resistor failure, which can severely impact your blower motor's performance, leaving you with erratic airflow or none at all. The resistor controls the speed of the blower motor, allowing you to adjust the airflow in your car's cabin. When it fails, you're often stuck with a single speed setting, or worse, the blower motor stops working entirely.

You might wonder how you can tell if the resistor is the culprit. Usually, signs include an inability to change the fan speed or the fan only working on its highest setting. This is since, without the resistor properly functioning to regulate voltage, the motor can't adjust to different speeds.

Why does the resistor fail, you ask? It mostly boils down to normal wear and tear. Over time, the resistor can overheat and burn out. Another common reason is corrosion because of exposure to moisture, which is more likely if your vehicle's cabin filter, which protects internal components from debris and moisture, isn't maintained. However, remember we're focusing on the resistor here, not the filter aspects.

If you're facing these issues, it's likely time to replace the resistor. It's a relatively affordable and straightforward fix that you can either do yourself, if you're handy and have the right tools, or have a professional handle. Ignoring it won't just leave you uncomfortable; it could also lead to further damage if the blower motor overworks itself trying to compensate for the failed resistor.

Clogged or Dirty Filters

Clogged or dirty filters can greatly reduce your blower motor's efficiency, leading to potential failures. When you neglect the regular maintenance of your HVAC system, the filters can get clogged with dust, pet hair, and other debris. This not only hampers the airflow but forces your blower motor to work harder than it should. Over time, this extra strain can cause the motor to overheat, wear out, and eventually stop working altogether.

You might be surprised at how a simple task like replacing or cleaning your filters can prevent such significant issues. Here's what happens when you let your filters get too dirty:

- Reduced airflow: The primary sign of a clogged filter is often a noticeable decrease in airflow. You might find that your rooms aren't getting as warm or cool as they used to, no matter how much you adjust the thermostat.

- Increased energy bills: As your blower motor strains to push air through clogged filters, it consumes more energy. You'll likely see this reflected in your monthly utility bills, with costs creeping up though your usage hasn't changed dramatically.

- Poor indoor air quality: Dirty filters can't trap contaminants as effectively, leading to dust, pollen, and other allergens circulating through your home. If you've noticed more sneezing or respiratory discomfort, it's time to check your filters.

Conclusion

To summarize, your blower motor can stop working due to different reasons. You might be dealing with blown fuses or relays, faulty wiring connections, a worn-out motor, resistor failure, or even clogged filters.

It's important to identify the root cause to fix the issue properly. Regular maintenance and prompt repairs can save you from the discomfort of a malfunctioning system. Don't wait until it's too late; keep your blower motor in check to make sure it's always running smoothly.