Worn-out tensioners

Misaligned pulleys

Debris

Extreme weather

Defective belts

These factors cause the drive belt to come off. Understanding the specific reason is essential for a durable solution.

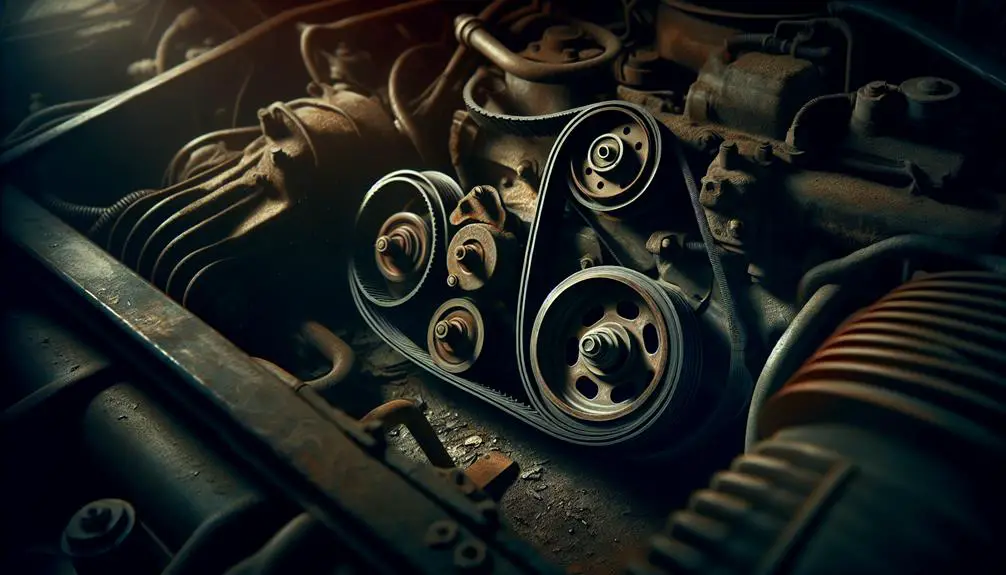

Worn-Out Belt Tensioners

One common reason your drive belt may come off is due to worn-out belt tensioners failing to properly maintain tension. This important component guarantees the belt operates smoothly, driving important parts like the alternator, water pump, and power steering pump. When tensioners age, their springs weaken, and the pulley bearings can seize, leading to inadequate tension on the belt. This slackness allows the belt to slip off its intended path, potentially leading to unexpected and inconvenient vehicle breakdowns.

To prevent this, it's important to inspect the tensioner during routine maintenance. Look for signs of wear, such as unusual noises or visible damage to the tensioner itself. Belt replacement is often necessary once you've identified a faulty tensioner. However, merely replacing the belt without addressing the underlying issue with the tensioner won't solve the problem long-term.

Moreover, tensioner lubrication is a preventive step you shouldn't overlook. Proper lubrication can extend the life of the tensioner, delaying the need for replacement. It's a straightforward yet effective way to ensure the longevity of both the belt and tensioner, keeping your vehicle running smoothly and reliably.

Misaligned Pulleys

While addressing tensioner issues is a key step in ensuring the drive belt functions properly, it's imperative to contemplate the alignment of pulleys. Misaligned pulleys can be a major culprit behind the frequent slippage or complete dislodgment of the drive belt. This misalignment could stem from a variety of factors, each affecting the belt's operational integrity.

- Pulley Wear: Over time, pulleys can undergo wear, altering their shape and surface. This wear can lead to a mismatch in the pulley's alignment. Since the drive belt relies on precise positioning to maintain tension and traction, any deviation in the pulley's alignment can cause the belt to wander off its intended path.

- Installation Errors: Incorrect installation of pulleys or related components can result in immediate misalignment. Even slight errors in positioning can have significant impacts, making it critical to ensure accuracy during installation processes.

- Physical Damage to Pulleys: Accidents or operational stress can cause physical damage to pulleys, warping their structure or shifting their position. This damage not only affects the pulleys themselves but the alignment within the belt drive system.

Understanding and rectifying these issues are fundamental to preventing drive belt malfunctions, ensuring a smoother and more reliable operation of your machinery.

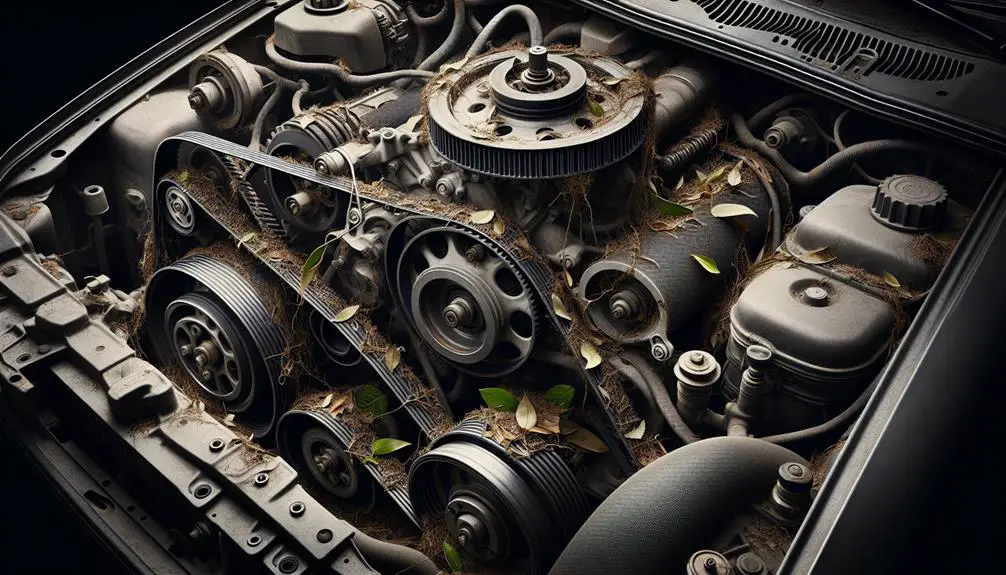

Debris Accumulation

Accumulation of debris within the drive belt system greatly contributes to its malfunction, as particles interfere with the belt's smooth operation. When you're dealing with a drive belt that keeps coming off, it's important to take into account the role that dirt, dust, and other foreign materials play in this issue. These contaminants can get lodged between the belt and the pulleys, causing the belt to misalign or even slip off entirely.

To tackle this problem, you'll need to adopt effective cleaning techniques. Start by visually inspecting the drive belt and pulley system for any visible debris. Use a soft brush or compressed air to gently remove dust and dirt from the belt's path. For more stubborn particles, a damp cloth might be necessary, but make sure the belt and pulleys are completely dry before reassembly to prevent slippage.

In addition, regular inspection tips include checking for signs of wear and tear on the belt itself, such as cracks or fraying, which can worsen the issue of debris accumulation. Always make sure that the belt is properly tensioned, as a loose belt is more susceptible to collecting debris.

Implementing these cleaning and inspection practices will reduce the risk of debris-related malfunctions in your drive belt system.

Extreme Weather Impact

Extreme weather conditions, ranging from sweltering heat to freezing cold, can greatly impact the performance and lifespan of your drive belt system. Comprehending how these conditions affect your drive belt is essential for maintaining its best function and preventing unexpected issues.

- Temperature Fluctuations: Sudden or extreme changes in temperature can cause the materials in your drive belt to expand and contract. Over time, this continuous cycle weakens the belt, making it more prone to slipping off or snapping. For instance, in scorching weather, the rubber in the drive belt can become overly soft and pliable, losing its tension and grip on the pulleys. Conversely, in freezing conditions, the belt becomes brittle and less flexible, increasing its risk of cracking.

- Humidity Effects: High humidity levels can introduce moisture into your drive belt system, affecting the belt's traction. The presence of moisture can cause the belt to slip off the pulleys, especially when starting your vehicle or operating under heavy loads.

- Corrosion and Material Degradation: Prolonged exposure to extreme weather can accelerate the degradation of the belt material. This is particularly true for vehicles operated in coastal areas where salt in the air can hasten corrosion, or in regions with high pollution levels, where acidic rain can deteriorate the belt material faster.

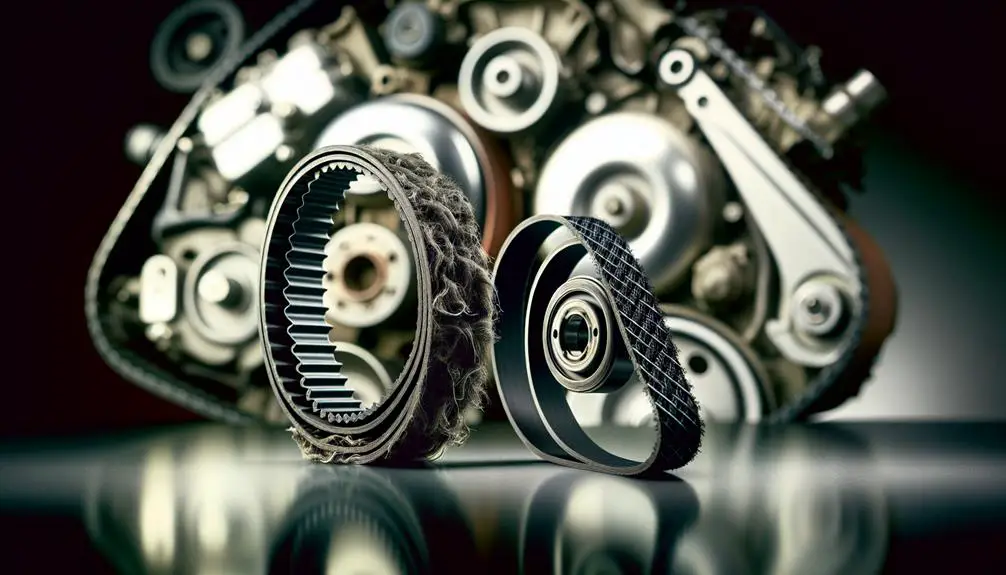

Defective Drive Belt

A defective drive belt, characterized by visible signs of wear such as cracks, fraying, or glazing, directly impacts your vehicle's performance and reliability. These defects often stem from two primary sources: material flaws and manufacturing defects. Material flaws refer to the quality of the rubber compound used to make the drive belt. If the rubber isn't up to standard, it can degrade faster under normal operating conditions, leading to premature wear and eventual failure. You'll notice this through excessive cracking or splitting on the belt's surface, signaling it's time for a replacement.

Manufacturing defects, on the other hand, involve errors during the production process. These can include improper vulcanization, misalignment of the belt's fibers, or incorrect sizing. Such defects mightn't be visible immediately but appear over time as the belt fails to maintain proper tension or alignment, causing it to slip off the pulleys.

It's important to inspect your drive belt regularly for these signs of defectiveness. Early detection allows you to address potential issues before they lead to more significant problems, such as engine overheating or battery drainage. Remember, a healthy drive belt is essential for the seamless operation of your vehicle's accessory systems.

Conclusion

To sum up, your drive belt can slip off because of several technical factors. Worn-out belt tensioners lose their grip, causing slippage. Misaligned pulleys disrupt the belt's path, leading to detachment. Accumulated debris obstructs the belt's movement, forcing it off course. Extreme weather can weaken the belt's material, reducing its efficacy. Finally, a defective drive belt, flawed from the start, is prone to failure.

Addressing these issues promptly guarantees the longevity and reliability of your vehicle's drive belt system.