The distributor is a key component of the ignition system in a vehicle. It serves the critical function of directing electrical current from the ignition coil to the spark plugs. This process must occur in the correct order and at the precise moment to ensure optimal engine performance.

The distributor achieves this by rotating at a synchronized speed with the engine. As it spins, it distributes high-voltage power to each spark plug in the firing order. This coordinated timing is essential for igniting the air-fuel mixture in each cylinder, ultimately powering the vehicle.

Distributor Basics

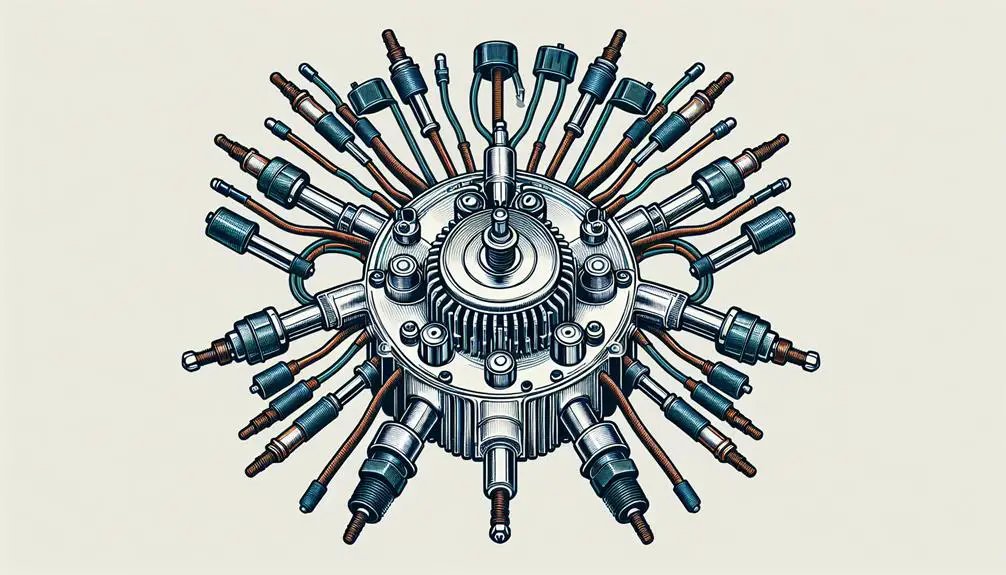

At its core, a distributor is a critical component in an ignition system, ensuring the timely and precise distribution of electrical energy to the spark plugs. You'll find it's composed of several key distributor components, each playing a pivotal role in the system's overall function. The rotor, cap, and points, alongside the vacuum and mechanical advance mechanisms, work in unison to direct high-voltage electricity from the ignition coil to the correct spark plug at the right moment.

The historical evolution of the distributor reveals a tale of technological advancement and refinement. Initially, the systems were mechanically simple but limited in precision and reliability. Over time, the introduction of electronic ignition systems dramatically enhanced the accuracy with which the distributor could time the delivery of electrical energy, greatly improving engine efficiency and performance. This evolution reflects not just changes in the distributor itself but also the broader shift towards more electronically controlled and efficient automotive systems.

Comprehending the distributor's components and their historical evolution gives you a solid foundation in grasping how critical this part is within the ignition system. It's a reflection of how automotive technology has advanced, ensuring your vehicle runs smoothly and efficiently.

Timing the Ignition

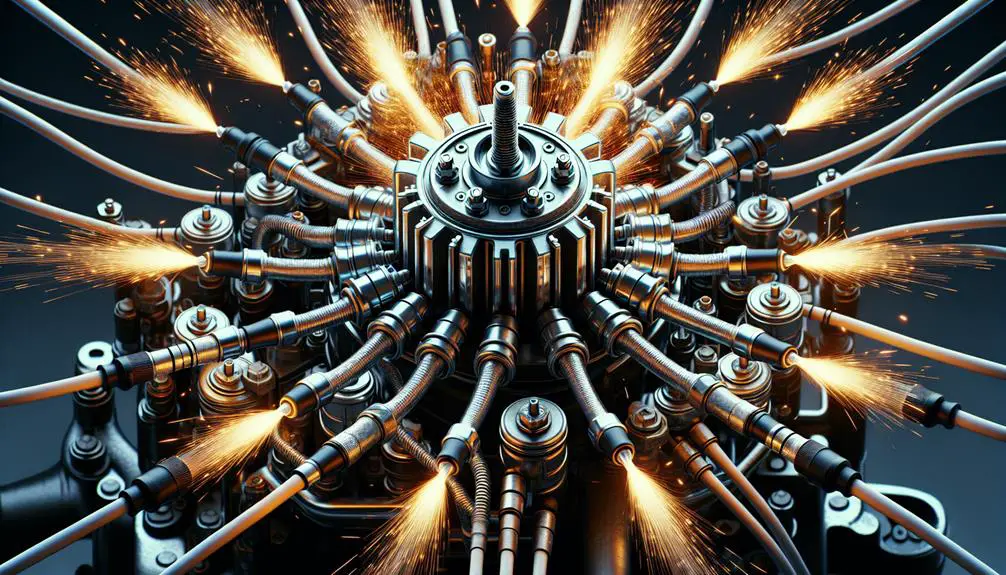

Comprehending the precise timing of ignition is pivotal, as it determines when the spark plugs ignite the fuel-air mixture in the engine's combustion chambers. This process isn't just about creating a spark; it's about doing so at exactly the right moment for maximum efficiency and power. The role of the distributor in this context is vital, as it's responsible for making sure spark plug synchronization. This means each spark plug fires at the best point in the engine's cycle, contributing to combustion optimization.

Achieving this synchronization requires a fine-tuned mechanism that can adjust the timing based on engine speed and load. As engine conditions change, the timing of the ignition must be adapted to maintain top performance. This adaptation prevents pre-ignition or knocking, which can lead to engine damage. The distributor's ability to adjust the timing ensures that the spark plugs fire with precision, maximizing the engine's power output and fuel efficiency.

Essentially, the distributor acts as the orchestra conductor for the engine's symphony, making sure each spark plug fires in harmony with the others. This orchestration is key to achieving seamless combustion optimization, directly impacting the vehicle's performance and longevity.

Directing Electrical Current

While orchestrating the ignition process, the distributor plays a crucial role in directing electrical current to the spark plugs. This component acts as a channel, making sure that current flow is precisely managed to promote best engine performance. The distributor's design allows it to receive high-voltage electrical current from the ignition coil and distribute it to each spark plug in the correct sequence. This distribution process is critical for the synchronized firing of spark plugs, which in turn ignites the air-fuel mixture within the engine's cylinders.

The mechanism by which the distributor directs current involves both mechanical and electrical principles. At its core, the distributor houses a rotating arm, known as the rotor, which passes close to a series of contacts connected to the spark plugs through high-tension leads. As the rotor spins, it sequentially aligns with these contacts, facilitating a controlled electrical breakdown across the gap. This breakdown allows the high-voltage current to jump from the rotor to the respective contact, thus directing the current flow to the spark plug.

This precise control over current flow and timing is crucial to avoid misfires and ensure efficient combustion. The distributor's ability to direct the electrical current accurately is foundational to maintaining the engine's rhythm and ensuring that power delivery is smooth and consistent.

Impact on Engine Performance

How does the distributor's efficiency in managing electrical currents influence engine performance?

The distributor plays a pivotal role in your vehicle's engine, acting as a gatekeeper for electrical currents that ignite the fuel-air mixture within the combustion chambers. This ignition is critical for engine startup and its subsequent operation. When the distributor functions at its best, it guarantees that the spark timing is precise. This precision directly affects fuel efficiency as well-timed sparks mean the fuel combusts at the ideal moment for maximum energy conversion.

Furthermore, the distributor's role extends to emission control. By making certain that the fuel burns completely, it reduces the emission of unburnt hydrocarbons, a common pollutant emitted from vehicles. Incomplete combustion not only wastes fuel but increases emissions, contributing to environmental pollution and violating emission standards.

Hence, the efficiency of the distributor isn't just about facilitating a smooth ride. It's about optimizing fuel consumption and minimizing the vehicle's environmental footprint. An efficiently functioning distributor guarantees that each spark occurs at the precise moment, leading to better fuel efficiency and stricter emission control. This interplay between precise electrical current management and engine performance underscores the distributor's critical role in modern automotive systems.

Maintenance and Troubleshooting

To guarantee your distributor maintains peak performance, regular maintenance and timely troubleshooting are essential. You've got to understand the specifics of cleaning techniques and be vigilant about replacement intervals to avoid performance dips or engine misfires.

Here's a concise guide to keep you on track:

| Maintenance Task | Recommended Action |

|---|---|

| Visual Inspection | Regularly check for wear and tear or any signs of corrosion. |

| Cleaning | Employ specialized cleaning techniques to prevent dirt and debris buildup. |

| Cap and Rotor Check | Inspect for cracks or carbon tracks and clean contacts. |

| Timing Adjustment | Periodically verify and adjust the ignition timing. |

| Replacement | Follow manufacturer's guidelines on replacement intervals for the distributor and its components. |

Conclusion

In summary, you've learned that the distributor plays a vital role in your vehicle's ignition system. By precisely timing the ignition and efficiently directing electrical current, it greatly impacts engine performance.

Regular maintenance and adept troubleshooting are necessary to guarantee its prime function. Understanding its mechanics and keeping it in top condition not only improves your vehicle's efficiency but also prevents potential engine issues, highlighting the distributor's pivotal role in automotive engineering.