- A faulty ignition coil

- Worn distributor caps

- Damaged rotor buttons

- A faulty ignition module

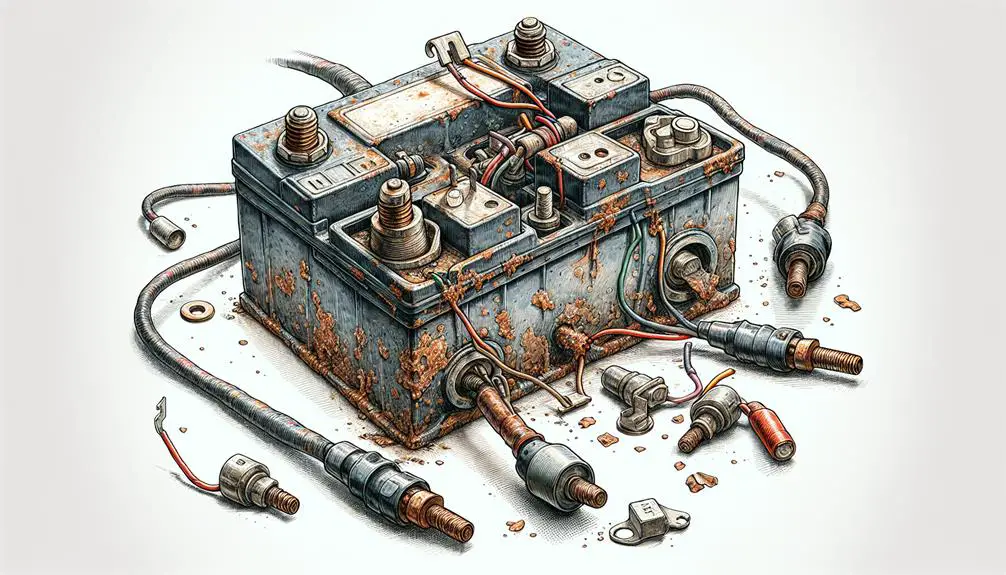

- Poor electrical connections

These issues can all cause your distributor to not get spark.

Faulty Ignition Coil

A faulty ignition coil can disrupt your vehicle's spark distribution, leading to engine performance issues. This critical component's primary function is to convert the battery's low voltage to the thousands of volts needed to create an electric spark in the spark plugs, igniting the fuel. When it's not working correctly, you'll likely experience misfires, a rough idle, or your car mightn't start at all.

Coil corrosion is a common culprit behind ignition coil failures. It's vital to inspect the coil for any signs of rust or corrosion, which can impede electrical conductivity. If you detect corrosion, it's time to replace the coil to restore proper functionality. Furthermore, make sure that the replacement coil is compatible with your vehicle's spark plugs. Mismatched components can lead to inefficient combustion and further engine troubles.

To maintain peak performance, regularly check the ignition coil for signs of wear or damage. Keeping an eye on coil corrosion and ensuring spark plug compatibility can save you from unexpected breakdowns and costly repairs. Remember, a well-maintained ignition system is key to a smoothly running engine.

Worn Distributor Cap

Having addressed ignition coil issues, another component that often causes spark distribution problems is the distributor cap, which can wear out over time. The distributor cap plays a pivotal role in directing the high voltage from the ignition coil to the spark plugs in the correct firing order. However, when it's worn, you might experience issues with your vehicle's ignition system.

One of the primary wear-related problems of a distributor cap is moisture intrusion and cap cracks. These issues can severely impact the functionality of your distributor cap, leading to misfires or no spark situation. Here's how you can identify signs of wear:

- Visual Inspection: Check for any physical damage like cracks or burns on the cap. These can allow moisture to seep in, which is detrimental to spark generation.

- Moisture Buildup: Look for signs of moisture inside the cap. Moisture intrusion can cause short circuits, preventing the spark from being properly distributed.

- Corrosion on Terminals: Corroded terminals can impede the flow of electricity, weakening the spark delivered to the spark plugs.

- Wear and Tear: General wear can lead to a poor fit with the distributor rotor, affecting the timing and strength of the spark.

If you notice any of these signs, it's likely time to replace your distributor cap. Doing so can restore the efficiency of your vehicle's ignition system, ensuring smooth starts and peak performance.

Damaged Rotor Button

After addressing distributor cap wear, it's crucial to inspect the rotor button, another key component susceptible to damage that can disrupt spark distribution. The rotor button is responsible for transferring the electrical charge from the ignition coil to the distributor cap and then to the spark plugs. Damage to the rotor button, such as cracks, burns, or excessive wear, can impede this critical transfer, leading to your vehicle's inability to start or run properly.

Corrosion issues and moisture intrusion are common culprits behind rotor button damage. Both can lead to poor electrical conductivity and eventual failure of the component. To make certain your distributor system functions optimally, here's a checklist to assess the health of your rotor button:

| Sign to Look For | Possible Cause |

|---|---|

| Physical damage (cracks, burns) | Excessive wear or high voltage |

| Discoloration | Overheating attributable to misalignment |

| Corrosion on the contact points | Moisture intrusion or age |

| Wear and tear | Regular use over time |

| Brittle or broken material | Poor quality or excessive age |

Faulty Ignition Module

Identifying issues with your ignition module is critical, as it plays a pivotal role in managing the timing and intensity of the engine's spark. A faulty ignition module can lead to a range of problems, including no spark from your distributor. One common sign of trouble is ignition timing issues, which can severely affect your vehicle's performance.

When diagnosing a faulty ignition module, look out for:

- Corroded terminals: Corrosion can impede electrical conductivity, leading to erratic or no spark.

- Intermittent engine stalling: This could indicate that the ignition module is failing to provide consistent spark.

- Engine misfires: Misfires often occur ensure improper timing of the spark, which can be traced back to a malfunctioning module.

- No start condition: If your engine refuses to start, a defective ignition module could be at the heart of the problem.

To address these issues, inspect the ignition module for visible signs of damage or corrosion. Use a multimeter to check for continuity and ensure the electrical connections are secure and not corroded. Replacing a faulty ignition module is usually straightforward but requires precision and careful adhere to your vehicle's repair manual to avoid further ignition timing issues.

Poor Electrical Connections

While addressing issues with the ignition module is a key step, don't overlook the role of poor electrical connections in causing a lack of spark from the distributor. Corroded terminals and loose wiring can greatly disrupt the flow of electricity, rendering your distributor ineffective. It's important to inspect every connection point, from the distributor cap to the ignition coil and spark plugs.

To start, examine the terminals for any signs of corrosion. Corroded terminals hinder the electrical conductivity, preventing the necessary voltage from reaching the spark plugs. If you find any corrosion, clean the terminals thoroughly with a wire brush or replace them if they're beyond repair.

Next, make sure that all wiring is secure and properly connected. Loose wiring can lead to intermittent electrical connections, which might cause your distributor to fail in delivering spark when needed. Check each wire for any signs of wear or damage. Frayed or exposed wires should be replaced immediately to prevent potential short circuits.

Conclusion

To sum up, if your distributor isn't sparking, it's likely because of a faulty ignition coil, a worn distributor cap, a damaged rotor button, a defective ignition module, or poor electrical connections.

You'll need to systematically inspect each component for wear or damage. Start by testing the ignition coil's functionality, then examine the distributor cap and rotor button for any signs of wear or damage. Check the ignition module next, and lastly, make sure all electrical connections are secure and corrosion-free for the best performance.