Blower motor noise can be caused by:

- Dust and debris buildup

- Worn bearings

- Loose components

- Electrical issues

- Blocked airflow

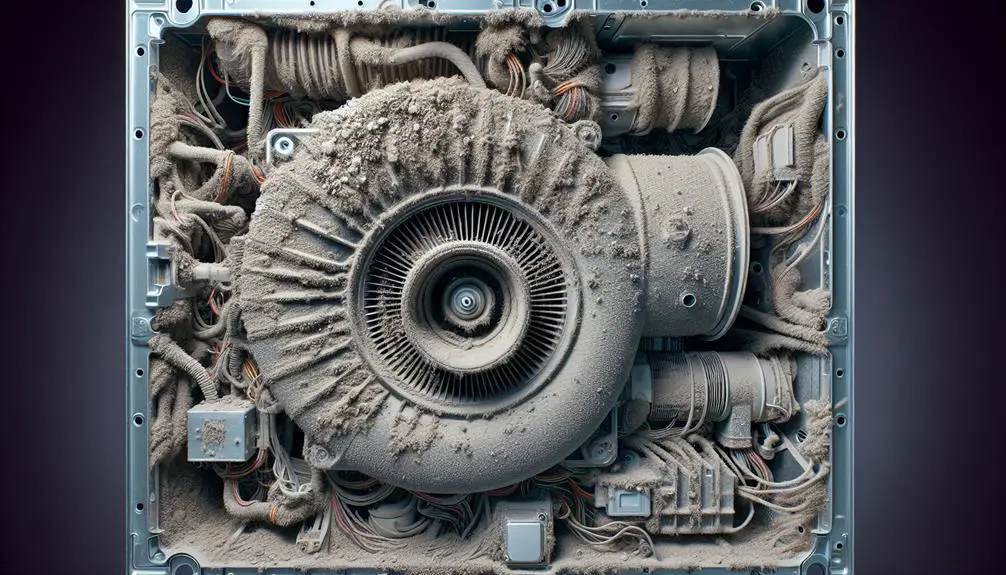

Dust and Debris Buildup

One common culprit behind blower motor noise is the accumulation of dust and debris. When you're cranking up your heating or cooling system, the last thing you want is an unsettling racket coming from the blower motor. It's not just an annoyance; it can signal that your system's efficiency is compromised. Often, the noise you're hearing is the result of dust, dirt, and other particles that have built up over time. These unwelcome guests can impede the fan blades' smooth rotation, causing them to hit accumulated debris or simply struggle to move through the gunk.

You might wonder how all that debris got there in the start. Well, your blower motor is constantly drawing in air from your home, which, no matter how clean you keep it, contains microscopic particles. Over time, these particles collect on the fan blades and within the motor housing. Regular maintenance, such as replacing or cleaning air filters, is your initial line of defense against this buildup. However, even with diligent care, some debris is bound to accumulate.

The solution isn't too complicated. A thorough cleaning of the blower motor and its components can often quiet down the noise. This might involve removing the fan blades to clean them individually and vacuuming out the motor housing. Remember, while you can tackle some of this maintenance yourself, don't hesitate to call in a professional if you're unsure. They can ensure your system isn't only quiet but running as efficiently as possible.

Worn Blower Motor Bearings

ARTICLE TITLE: Blower Motor Noise: Explained

PREVIOUS SUBTOPIC: 'Dust and Debris Buildup'

CURRENT SUBTOPIC: 'Worn Blower Motor Bearings'

Another common cause of blower motor noise stems from worn bearings, a problem that can drastically reduce your system's efficiency and performance. When the bearings in your blower motor wear out, they can't hold the motor shaft in place as precisely as before. This lack of stability causes the shaft to wobble, leading to vibrations and noise. You'll often hear a grinding or squealing sound, signaling it's time to inspect the bearings.

Bearings wear out because of age, excessive use, or lack of maintenance. Regularly checking and lubricating the bearings can extend their life and maintain your system's performance. However, once they're worn, replacement is your best bet to restore quiet operation and efficiency.

Here's a quick guide to understanding the impact of worn bearings and what you should do about it:

| Sign of Wear | Action to Take |

|---|---|

| Grinding noise | Inspect bearings |

| Squealing sound | Lubricate or replace bearings |

| Reduced efficiency | Replace bearings |

Ignoring worn bearings not only keeps your environment noisy but can lead to further damage, affecting other parts of the blower motor and increasing repair costs. So, if you're noticing unusual sounds coming from your blower motor, don't wait. Check the bearings and take the necessary steps to fix the issue. Keeping your blower motor in top shape ensures a quieter, more efficient system you can rely on.

Loose or Damaged Components

Beyond worn bearings, loose or damaged components in your blower motor can lead to disruptive noises and reduced system efficiency. It's important you don't overlook these issues, as they can quickly escalate into more significant problems. Let's explore what you should watch out for and how to address these concerns.

First, the mounting bolts that hold your blower motor in place can loosen over time. This might seem minor, but it allows the motor to vibrate excessively, producing a rattling or buzzing noise that you can't ignore. You should periodically check these bolts and tighten them if necessary. It's a simple step that can save you a lot of headaches down the line.

Next, consider the fan blades attached to the blower motor. If they're bent or damaged, they won't rotate smoothly, creating an uneven airflow and unusual sounds. Inspect the blades for any signs of damage and replace them if they're beyond repair. Remember, the smoother the blades rotate, the quieter and more efficient your system will be.

Lastly, don't forget about the blower motor's housing. Cracks or breaks in the housing can't only produce unwanted noise but also affect the motor's performance. Examine the housing carefully for any damage and consider replacing it if you find significant issues.

Addressing loose or damaged components early on can prevent further damage and ensure your blower motor runs quietly and efficiently. Don't wait until the noise becomes unbearable; take action as soon as you notice something's amiss.

Electrical Issues

Shifting our focus to electrical issues, it's significant to recognize that faulty wiring or connections can also cause your blower motor to produce strange noises. When you're dealing with a vehicle or home HVAC system, the electrical components play a vital role in ensuring everything runs smoothly. If there's a short circuit, loose connection, or damaged wire somewhere in the system, it can lead to intermittent or continuous odd sounds coming from the blower motor.

It's vital to realize that electricity is what powers the blower motor, enabling it to circulate air throughout the system. If the electrical supply isn't stable or is interrupted, the motor may struggle to perform efficiently. This struggle often displays as humming, buzzing, or clicking sounds, which you might mistake for a mechanical issue.

Additionally, a failing capacitor, which is responsible for providing the necessary jolt to start the motor, can also be the culprit behind the noise. When capacitors wear out, they can cause the motor to start slowly, producing a loud humming noise until it reaches full operational speed.

Addressing electrical issues isn't something you should take lightly. Unlike mechanical problems, which might be somewhat straightforward to diagnose and fix, electrical problems require a keen understanding of the system's wiring diagram and a safe approach to handling electrical components.

If you're not experienced with electrical systems, it's wise to call in a professional. They can safely inspect the wiring, connections, and components like capacitors to pinpoint and fix the issue, ensuring your blower motor runs quietly and efficiently once more.

Blocked Airflow

Another common cause of blower motor noise is blocked airflow, which can greatly strain the system. When air can't move freely through your HVAC system, the blower motor works harder, leading to unusual sounds. Imagine trying to breathe with a cloth over your mouth; that's how your blower feels with a blocked airflow.

Blocked airflow often results from dirty or clogged air filters. These filters trap dust, pollen, and other particulates to keep your indoor air quality high. However, if you don't replace or clean them regularly, they can become so clogged that air struggles to pass through. This not only puts extra strain on the blower motor but can increase your system's efficiency and increase your energy bills.

But it's not just dirty filters that can cause trouble. Blockages can occur in the ductwork as well. Over time, ducts can accumulate dust, debris, or even get partially crushed or blocked by furniture or other household items, restricting airflow. Regular duct cleaning and keeping vents clear of obstructions can help prevent these issues.

To minimize the risk of blocked airflow, check and replace your air filters every 1-3 months, depending on your system's requirements and your indoor air quality. Consider having your ductwork inspected and cleaned every few years by a professional. By taking these steps, you'll not only reduce the noise from your blower motor but improve your HVAC system's performance and longevity.

Conclusion

To sum up, if your blower motor's making noise, it's likely because of:

- dust and debris buildup

- worn bearings

- loose or damaged components

- electrical issues

- blocked airflow

You've got a few potential culprits to check out. Regular maintenance can prevent some of these issues, but sometimes parts wear out or unexpected problems crop up.

Don't ignore the noise—addressing it promptly can save you from more significant, costly repairs down the line. Keep your system clean and in good working order to minimize disruptions.