Your distributor won't come out due to corrosion, rust, or previous improper installations.

Navigating the complexities of distributor removal can be challenging, with issues like corrosion, rust, and prior incorrect installations acting as significant obstacles.

Yet, understanding the mechanics and common problems can make this task more approachable.

In this guide, you'll learn why your distributor seems to have made itself a permanent fixture and discover strategies that could persuade it to relinquish its tight grip.

Understanding Distributor Mechanics

To grasp why your distributor might be stubbornly refusing to budge, it's key to initially comprehend its mechanics, starting with its role as the heart of your vehicle's ignition system, precisely timing the spark to ignite the fuel-air mixture in each cylinder. This process, known as ignition timing, is critical for your engine's performance and efficiency. The distributor, housing a rotor and a distributor cap, plays a pivotal role in this.

The distributor cap, an essential component, routes the voltage from the ignition coil to the spark plugs in the correct firing order. This is important for the engine to run smoothly. If the ignition timing is off, your engine mightn't run or could suffer from poor performance. The timing is adjusted by rotating the distributor, a task that requires precision.

Understanding the mechanics of the distributor and the importance of the distributor cap and ignition timing helps you appreciate the precision involved in these components' operation. This knowledge is fundamental when you're trying to diagnose why your distributor won't come out. It's not just a piece you can yank out; it's integrated into your vehicle's performance.

Common Removal Hurdles

When attempting to remove your distributor, you'll likely encounter several common hurdles, including corrosion, tight spaces, and misalignment. These challenges can be intimidating but grasping them can ease the removal process.

Initially, consider engine compatibility. Not all distributors fit every engine model seamlessly. A mismatch can lead to a distributor being jammed or improperly seated, complicating its removal. It's critical to verify that the distributor is suitable for your engine type to avoid such issues.

Another significant obstacle is lubrication neglect. Over time, the moving parts of a distributor can suffer from lack of lubrication. This negligence can lead to the distributor seizing up, making it difficult to remove. Regular maintenance, including proper lubrication, is vital to make sure that the distributor remains operable and can be removed when necessary.

Dealing with tight spaces requires attention as well. Modern engines are often compact, leaving little room to maneuver tools or your hands. This constraint can make it challenging to grip and extract the distributor. Using the right tools, such as a distributor wrench designed for tight spaces, can make this task more manageable.

Grasping these hurdles and preparing for them can greatly simplify the process of removing your distributor.

Corrosion and Rust Issues

Comprehending the common removal hurdles sets the stage for tackling one of the most persistent problems: corrosion and rust issues on the distributor. These issues aren't just superficial; they can lead to significant damage, making the distributor difficult, if not impossible, to remove without causing further harm.

Corrosion and rust form because of a combination of material compatibility and environmental factors. When the distributor's materials react negatively with elements such as moisture, salt, or even the chemicals in the air, corrosion sets in. This is particularly problematic in areas with high humidity or in vehicles exposed to road salt during winter.

To effectively address corrosion and rust, consider the following steps:

- Identify the Materials: Know what your distributor and the surrounding components are made of. Material compatibility plays a significant role in preventing corrosion.

- Regular Inspections: Catching rust early can prevent it from spreading and causing more severe damage.

- Environmental Protection: Implement protective measures against environmental factors. This could include using corrosion inhibitors or ensuring your vehicle is stored in a less harsh environment.

Tackling corrosion and rust involves a proactive approach. Comprehending the underlying causes and taking preventive measures can save you from the frustration of a stuck distributor.

Improper Installation Symptoms

Recognizing the symptoms of improper installation is vital for ensuring your distributor functions at its best and avoids potential damage to your vehicle's engine. When the distributor isn't installed correctly, you'll likely notice a decline in engine performance. This can appear as rough idling, unexpected stalling, or difficulty starting your vehicle. These issues arise since the distributor plays a critical role in managing the timing and distribution of the spark to the engine's cylinders.

Another telltale sign of improper installation is irregular ignition timing. If the distributor isn't aligned or seated correctly, the timing of the spark delivered to each cylinder can be off. This misalignment can lead to the engine running too rich or too lean, which not only affects performance but can also cause long-term damage to the engine. You might hear knocking sounds from the engine or experience a noticeable lack of power during acceleration.

Monitoring these symptoms closely can save you from more serious issues down the line. If you're experiencing any of these problems, it's likely a sign that the distributor installation needs to be reevaluated.

Solutions and Preventative Measures

After identifying the symptoms of improper distributor installation, it's important to investigate effective solutions and preventative measures to maintain peak engine performance. Addressing these issues promptly can save you from a variety of engine troubles down the line. Here are some key strategies:

- Lubrication techniques: Regularly applying the correct type of lubricant to the distributor shaft can prevent seizing and corrosion. Choose a lubricant that's suitable for high temperatures and has anti-corrosive properties. This step guarantees smooth rotation and extends the life of the distributor.

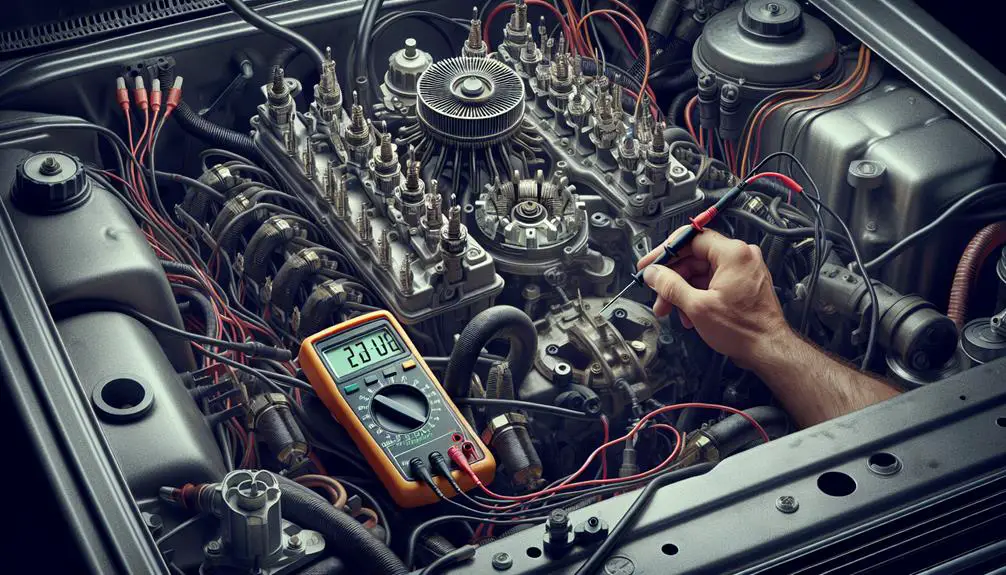

- Electrical diagnostics: Conduct thorough electrical diagnostics to check for any wiring issues or shorts that might affect the distributor's performance. Using a multimeter, verify the integrity of the distributor's electrical connections and make sure they're secure and free from corrosion. This can prevent unexpected failures and ensure consistent electrical flow.

- Routine inspection and maintenance: Implement a schedule for inspecting the distributor for signs of wear, misalignment, or damage. Regular checks allow for early detection of potential problems, reducing the risk of improper installation and ensuring the distributor operates efficiently.

Conclusion

To sum up, if you're having difficulty removing your distributor, it's likely because of corrosion, rust, or previous improper installation. Grasping the mechanics of the distributor is essential for diagnosing these common hurdles.

To prevent future issues, always guarantee correct installation and adopt regular maintenance practices. Applying anti-seize compound can combat rust, while periodic inspections can catch early signs of corrosion.

Remember, tackling these challenges early on is vital for maintaining your vehicle's ignition system's health and performance.