Blower motor failures can be caused by a blown fuse.

Blower motor failures can also be caused by a faulty motor.

Common Causes

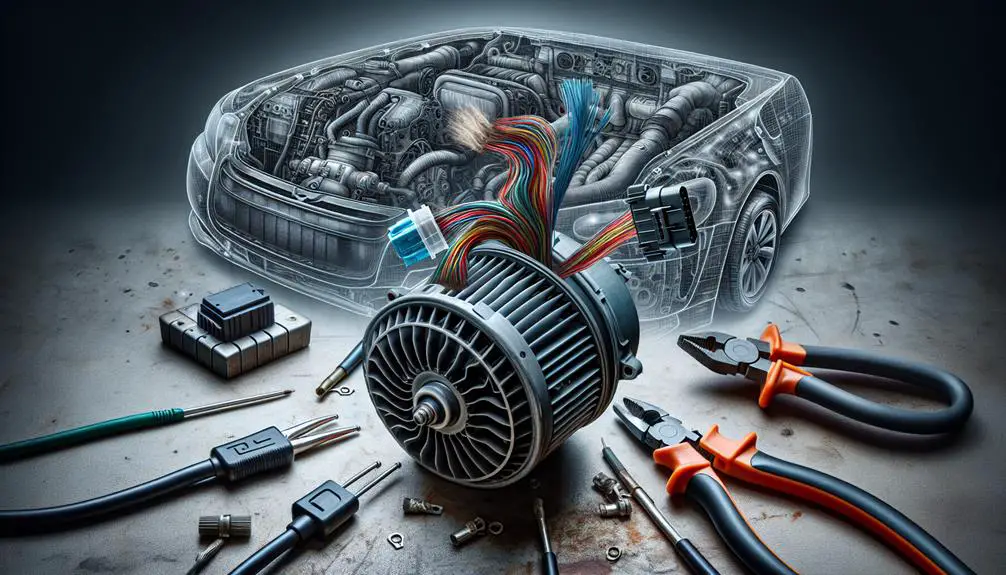

Several factors can cause your blower motor to stop working, including a blown fuse, a faulty relay, or a burned-out motor. When you're facing a situation where your vehicle's blower isn't functioning, it's important to take these common culprits into account as they're often at the heart of the problem.

A blown fuse is a common cause. It acts as the guardian of your car's electrical system, and when it detects an overload, the fuse blows to protect the system. This means if your blower motor suddenly stops, checking the fuse should be your initial step. It's a simple check and an even simpler fix if that turns out to be the issue.

Faulty relays are another common villain. These components are responsible for sending power to the blower motor. If the relay fails, the motor won't receive the power it needs to run. Relays can wear out over time or fail suddenly, and diagnosing this issue might require a bit more knowledge about your vehicle's electrical system.

Finally, the motor itself could be the issue. Over time, blower motors can burn out, especially if they're frequently used at high speeds or have been in service for many years. A burned-out motor will need to be replaced, as repairs are often not feasible or cost-effective.

Comprehending these common causes can save you time and frustration when troubleshooting your blower motor issues. It's the initial step in getting your system back up and running, ensuring you stay comfortable no matter the weather outside.

Troubleshooting Tips

Before plunging into a costly repair, let's investigate some practical troubleshooting tips to pinpoint the issue with your blower motor.

To start with, check the fuse associated with your blower motor. A blown fuse is often a quick and easy fix. Locate your vehicle's fuse box, find the blower motor's fuse using the diagram in your owner's manual, and see if it's intact. If it's blown, replacing it might just solve your problem.

Next, don't overlook the blower motor resistor. This component controls the speed of the blower motor. If it fails, the blower motor mightn't work at all or only work at one speed. Accessing the resistor usually involves removing the blower motor or a panel near it. If it looks corroded or burnt, it's time for a replacement.

Then, give the blower motor itself a direct test. Disconnect it from the vehicle's electrical system and try powering it directly with a separate power source, like a battery. If it doesn't spin freely or at all, the motor itself is likely the culprit and needs replacing.

Lastly, make sure the ventilation controls on the dashboard are functioning properly. Sometimes, the issue isn't with the blower motor but with the controls that command it. If they're unresponsive or erratic, the control unit might need attention.

Electrical Issues Explained

Delving into the heart of your vehicle's blower motor problem, it's crucial to grasp the electrical issues that might be at play.

To start off, your blower motor relies on a consistent supply of electricity to function. If there's a break or fault in the circuit, it won't work. This could be because of blown fuses. They're designed to protect the circuit by breaking when there's an overload. Check your vehicle's manual to locate the fuse connected to the blower motor. If it's blown, replacing it might solve the problem.

Next, consider the blower motor resistor. It controls the speed of the blower motor. When it fails, it often results in the blower motor operating at a single speed or not working at all. It's usually located near the blower motor and is relatively inexpensive and straightforward to replace.

Don't overlook the wiring itself. Over time, wires can fray, corrode, or disconnect, disrupting the electrical flow. Inspect the wiring for any visible signs of wear or damage. Sometimes, a simple reconnection or replacement of a wire is all that's needed.

Finally, the issue might lie with the blower motor's relay. This component acts as a switch, allowing electricity to reach the blower motor. A faulty relay can prevent the motor from receiving power. Testing or replacing the relay might be necessary if other electrical components appear to be in good condition.

Comprehending these potential electrical issues can help you pinpoint the cause of your blower motor's malfunction. Remember, dealing with electrical components requires caution, so always make your safety first.

Professional Repair Advice

If you're unsure about tackling the blower motor issues on your own, consulting a professional mechanic can provide peace of mind and guarantee the job's done right. Dealing with a malfunctioning blower motor can be tricky, and sometimes the best course of action is to let an expert take the helm. Here's why seeking professional help can be your best bet:

- Diagnosing the Problem Accurately: Mechanics have the tools and expertise to diagnose the issue quickly and accurately. They can determine whether the problem lies with the blower motor itself, the wiring, or perhaps a different component entirely. This precision saves you time and money, preventing unnecessary replacements or repairs.

- Access to the Right Tools and Parts: Professionals have access to the necessary tools and replacement parts. They can source quality parts that mightn't be readily available to the average consumer, ensuring a repair that lasts.

- Warranty on Repairs: Many mechanics offer a warranty on the work performed, giving you an added layer of protection. If the issue recurs within the warranty period, they'll fix it at no extra cost.

- Safety: Tinkering with your car's electrical system can be dangerous if you're not sure what you're doing. A professional mechanic knows how to handle these systems safely, reducing the risk of injury or further damage to your vehicle.

Preventative Maintenance Tips

To keep your blower motor running smoothly, it's important to adhere to regular maintenance schedules. Regular checks and maintenance can prevent the most common issues that lead to blower motor failures. Let's delve into some preventative maintenance tips that'll help you keep your blower motor in top condition.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Check and replace the filter | Every 1-3 months | Ensures airflow and reduces strain on the motor |

| Inspect wiring and connections | Bi-annually | Prevent electrical failures |

| Clean the blower motor and surrounding area | Annually | Removes debris and prevents overheating |

| Lubricate moving parts | As needed or annually | Reduces wear and tear |

| Professional inspection | Annually | Identifies potential issues early |

To begin with, you should regularly check and replace the air filter. A clogged filter restricts airflow, forcing the blower motor to work harder, which can lead to overheating and failure. Ideally, you'd do this every one to three months, depending on usage and the environment.

Inspecting the wiring and connections bi-annually can help prevent electrical issues that might cause the blower motor to stop working. Look for signs of wear or damage, and address them promptly.

Cleaning the blower motor and its surrounding area annually is also crucial. Dust and debris can accumulate, causing the motor to overheat. While you're at it, lubricating any moving parts can reduce wear and tear, prolonging the life of your blower motor.

Conclusion

In sum, if your blower motor isn't working, it's likely because of a few common causes. Start by troubleshooting with our tips, paying special attention to potential electrical issues.

If you're stuck, don't hesitate to seek professional repair advice. Remember, regular preventative maintenance can save you from headaches down the road. By staying proactive, you'll keep your blower motor running smoothly and avoid unexpected breakdowns.

Stay informed, stay prepared, and you'll navigate this issue with ease.