Hyundai 2.5 Turbo engines may exhibit symptoms like oil consumption, unusual noises, and reduced performance. Causes range from design flaws to maintenance lapses. Regular oil changes, coolant checks, and adherence to service intervals are key preventive measures. Troubleshooting should start with diagnostic codes, followed by checks of oil levels, turbo components, and fuel systems. For complex issues, professional assistance ensures accurate diagnosis and quality repairs, especially for warranty-covered or recall-related work.

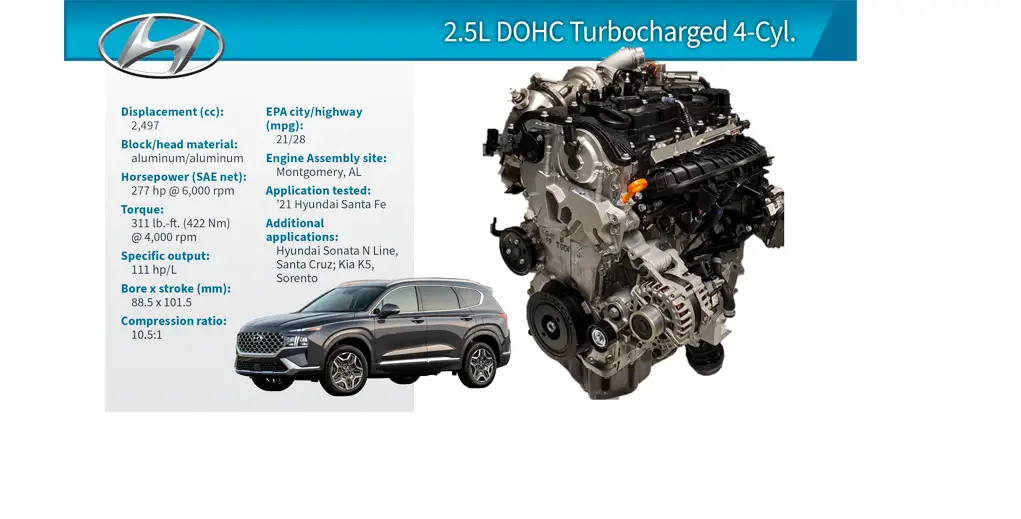

Common Issues with Hyundai 2.5 Turbo Engines

Engine Reliability and Performance Concerns

Hyundai’s 2.5 Turbo engines, like any other engines, can experience a range of issues that may affect their performance and reliability. Some of the common problems reported by users include:

- Oil Consumption: High oil consumption has been reported, which can lead to low oil levels and potentially cause engine damage if not monitored and addressed promptly.

- Engine Noise: Some users have reported noises from the engine bay, which could be due to various factors, including loose components or more serious internal engine issues.

- Coolant Leaks: There have been instances where antifreeze vapor seeps into the engine area when the vehicle is turned off, causing a strong coolant smell. This could indicate a cooling system problem that may affect engine temperature regulation.

- Fuel System Issues: For certain models with the 2.5L turbo engine, there have been recalls due to potential fuel leaks, which pose a fire risk.

- Engine Stalling: Faulty fuel pumps have led to engine stalling, which can be dangerous if it occurs while the vehicle is in motion.

- Turbocharger Problems: Turbocharged engines can suffer from issues such as low boost, which can be indicative of a failing turbocharger or related components.

Safety Implications

The problems associated with Hyundai’s 2.5 Turbo engines can have significant safety implications:

- Engine Fires: The risk of engine fires is a serious safety concern. Fuel leaks, oil leaks, or severe engine damage due to a failed connecting rod bearing can lead to fires, posing a threat to occupants and property.

- Stalling: An engine that stalls while driving can lead to loss of vehicle control, increasing the risk of accidents.

- Overheating: Coolant leaks and high oil consumption can lead to engine overheating, which may cause the engine to seize and potentially result in a breakdown or fire.

- Reduced Performance: Issues like low boost from the turbocharger can lead to reduced engine performance, which may affect the vehicle’s ability to accelerate or maintain speed, especially in situations where quick maneuvering is necessary.

Preventative Measures and Maintenance

To mitigate these issues, regular maintenance and prompt attention to any warning signs are crucial. This includes:

- Regularly checking and topping up engine oil and coolant levels.

- Paying attention to any unusual noises or smells from the engine bay and seeking immediate professional diagnosis.

- Adhering to the manufacturer’s recommended service intervals and using quality replacement parts.

- Being aware of recalls and technical service bulletins (TSBs) for your specific vehicle model and ensuring that any necessary repairs or updates are carried out by a qualified technician.

Hyundai has also taken steps to address some of these issues through recalls and software updates, such as the knock sensor detection system (KSDS) update designed to detect early signs of connecting rod bearing failure.

Symptoms of 2.5 Turbo Engine Problems

Recognizing the early signs of engine problems in vehicles with a 2.5 Turbo engine is crucial for maintaining performance and preventing more severe damage. Here are some common symptoms that drivers should be aware of:

1. Unusual Engine Noises

- Knocking, Ticking, or Grinding Noises: These sounds can indicate internal engine problems, such as bearing failure or issues with the turbocharger itself.

2. Oil and Coolant Issues

- High Oil Consumption: If the engine requires frequent top-ups of oil, it could be a sign of internal wear or leaks.

- Coolant Leaks: Signs of coolant leakage or a strong coolant smell, especially after the engine has been turned off, can indicate a failing head gasket or problems in the cooling system.

3. Smoke and Exhaust Problems

- Excessive Smoke: Blue smoke from the exhaust indicates oil burning, while white smoke can be a sign of coolant entering the combustion chamber.

4. Performance Issues

- Reduced Power and Sluggish Acceleration: If the turbo fails to provide the necessary boost, it can result in noticeable power loss and poor acceleration.

- Lurching or Stuttering: This can occur particularly under load or when accelerating, indicating potential issues with fuel delivery or turbo performance.

5. Turbocharger Specific Symptoms

- Low Boost: A turbocharger not achieving the required boost levels can be symptomatic of a variety of issues, including leaks in the intake system or a failing turbo.

- Oil in Intake or Exhaust Systems: Presence of oil in these areas can indicate a seal failure in the turbocharger.

6. Engine Management Warnings

- Illuminated Check Engine Light: This can be triggered by a range of engine issues, including sensor failures, emissions problems, or turbocharger malfunctions.

7. Physical Inspection Findings

- Oil Residue Around the Turbo: Visible oil or grime buildup around the turbocharger can indicate leaking seals.

- Shaft Play in Turbo: Checking the turbocharger for any play in the shaft can help identify wear or damage before complete failure occurs.

Early Recognition and Action

To catch these issues early, drivers should:

- Regularly Check Fluid Levels: Monitoring oil and coolant levels can help catch leaks early.

- Listen for Unusual Noises: Being attentive to the sounds your engine makes can help identify problems before they escalate.

- Watch for Smoke: Noticing changes in exhaust smoke can be an early indicator of internal issues.

- Pay Attention to Engine Performance: Any deviation in driving performance, such as reduced power or unusual engine behavior, should be investigated.

- Heed Warning Lights: Always take engine warning lights seriously and seek professional diagnostic services.

Causes of 2.5 Turbo Engine Problems

The root causes behind Hyundai 2.5 Turbo Engine issues can be multifaceted, involving various factors that contribute to the development of these problems. Based on the provided sources, here are some of the key factors that have been identified:

Design and Manufacturing Flaws

- Piston Design: The Smartstream 2.5L engines have been reported to have poor piston ring and piston fit design, which can lead to issues such as oil consumption, piston slap, and ultimately engine failure.

- Combustion Temperatures: The GDI half of the GDI/MPi combined system in the Smartstream engines is designed to run at very high combustion temperatures, which can lead to excessive blowby and carbon buildup.

- Oil Pump and Oil Flow: There have been allegations of oil flow problems in Hyundai engines, potentially due to design flaws that cause premature internal engine failure.

Component Failures

- Turbocharger Issues: Low boost pressure from the turbocharger can be caused by a faulty turbocharger, air leaks, or a malfunctioning wastegate, leading to reduced engine performance.

- Fuel System Problems: Recalls have been issued for potential fuel leaks in certain models, which pose a fire risk and can impact engine performance.

Maintenance and Operational Factors

- Oil Consumption: High oil consumption has been reported, which can lead to low oil levels and engine damage if not monitored and addressed.

- Coolant Leaks: Coolant leaks can lead to overheating and serious engine damage. A common cause of coolant leaks in turbo engines is a faulty radiator cap.

- Inadequate Maintenance: Neglecting regular maintenance, such as oil and filter changes, can lead to oil starvation and engine overheating.

Software and Sensor Issues

- Knock Sensor Detection System (KSDS): Hyundai has installed software updates on some vehicles to detect early signs of connecting rod bearing failure. However, there have been instances where dealerships did not perform the recall repairs they claimed to have done, necessitating further recalls.

External Factors

- Fuel Quality: Bad batches of fuel can adversely affect engine performance and may lead to engine damage.

Warranty and Dealer Response

- Warranty Coverage: Hyundai offers a 10-year/100,000-mile warranty, which may provide some reassurance to owners facing engine issues. However, the prevalence of engine replacements suggests that there are underlying issues with these engines.

Preventive Maintenance of Hyundai 2.5 Turbo Engine Problems

Preventive maintenance is crucial in avoiding common problems with the Hyundai 2.5 Turbo engine and ensuring the longevity and reliability of the vehicle. Regular maintenance can help identify potential issues before they become serious, saving time and money on repairs. Here are some tips and recommendations for keeping the Hyundai 2.5 Turbo engine in good condition:

Regular Oil Changes

- Timely Oil Changes: Follow the manufacturer’s recommended oil change intervals. For the Hyundai Santa Fe, the first oil change is recommended at around 7,500 to 8,000 miles or approximately six months after purchase.

- Oil Quality: Use the correct grade of motor oil for your engine type and climate conditions. Hyundai has specific oil requirements for their 2.5 and 2.5T engines, such as 0W-20 for the NA and 0W-30 for the turbo.

Inspection and Replacement of Filters

- Air Filter Maintenance: Inspect and replace the air filter regularly to ensure proper airflow to the engine.

- Climate Control Air Filter: Replace the climate control air filter as per the maintenance schedule to maintain air quality and HVAC system efficiency.

Cooling System Care

- Coolant Level Checks: Regularly check the coolant level and look for signs of leaks or a strong coolant smell, which could indicate a problem with the cooling system.

Fuel System Maintenance

- Fuel Additives: Use fuel additives as recommended during maintenance to help keep the fuel system clean.

- Fuel Injector Cleaning: Keep the fuel injectors clean to prevent weak spray patterns and poor combustion.

Turbocharger Check

- Turbo Inspection: Inspect the turbocharger for oil residue or shaft play, which can indicate wear or damage.

Battery and Electrical System

- Battery Inspection: Regularly inspect the battery to ensure it is charging correctly and has no corrosion.

Brake System

- Brake Inspection: Have the brakes inspected regularly for wear and proper function.

Tire Maintenance

- Tire Rotation: Rotate the tires as per the recommended intervals to ensure even wear and extend tire life.

Use of Genuine Parts

- Genuine Parts: Use genuine Hyundai parts for replacements to ensure compatibility and reliability.

Adherence to Service Intervals

- Service Intervals: Adhere to the recommended service intervals, which may vary based on driving conditions and vehicle usage.

Monitoring for Symptoms

- Vigilance: Be vigilant for any signs of engine trouble, such as unusual noises, smoke, or a decrease in performance, and address them promptly.

Professional Service

- Certified Service: Have your vehicle serviced at a certified Hyundai service center where technicians are trained to work on Hyundai vehicles and can perform comprehensive inspections.

Troubleshooting Guide for Hyundai 2.5 Turbo Engine Problems

Troubleshooting engine problems in a Hyundai 2.5 Turbo can be complex, but by following a systematic approach, you can identify and address many common issues. Here’s a step-by-step guide to help you diagnose and troubleshoot these engine problems effectively:

Step 1: Check Engine Light and Diagnostic Codes

- Tool Required: OBD-II scanner.

- Procedure: Connect the scanner to the OBD-II port under the dashboard. Read any diagnostic trouble codes (DTCs) that are present. These codes will provide clues about the systems or components causing issues.

Step 2: Inspect for Oil and Coolant Levels

- Procedure: Check the oil and coolant levels. Low oil can indicate leaks or high oil consumption. Low coolant levels might suggest leaks in the cooling system.

- Common Fixes: Top up fluids to the recommended levels. Investigate for leaks if levels are low. Replace damaged seals or gaskets as needed.

Step 3: Listen for Unusual Noises

- Procedure: Start the engine and listen carefully for any knocking, ticking, or grinding sounds.

- Common Fixes: If you hear unusual noises, it could indicate issues such as bearing wear or turbocharger problems. A professional mechanic should further investigate these sounds.

Step 4: Check for Smoke from Exhaust

- Procedure: Observe the exhaust while the engine is running. Blue smoke indicates oil burning; white smoke suggests coolant leakage into combustion chambers.

- Common Fixes: For oil burning, check and replace worn piston rings or valve seals. For coolant leakage, inspect the head gasket and replace if necessary.

Step 5: Turbocharger Inspection

- Procedure: Inspect the turbocharger for any signs of oil leakage, shaft play, or damage to the turbine blades.

- Common Fixes: Replace the turbocharger if it shows significant wear or damage. Ensure all connecting hoses and pipes are secure and leak-free.

Step 6: Fuel System Check

- Procedure: Inspect the fuel lines and connections for leaks. Check the fuel pressure with a fuel pressure gauge.

- Common Fixes: Replace any damaged or worn fuel lines. If the fuel pressure is low, consider replacing the fuel pump or cleaning the fuel injectors.

Step 7: Perform Compression Test

- Tool Required: Compression tester.

- Procedure: Remove the spark plugs and screw in the compression tester into one spark plug hole at a time. Crank the engine and note the compression reading for each cylinder.

- Common Fixes: Low compression in one or more cylinders can indicate issues such as worn piston rings or damaged cylinder heads. These components may need to be replaced.

Step 8: Check and Clean the Intake Valves

- Procedure: Inspect the intake valves for carbon buildup, which is common in direct injection engines.

- Common Fixes: Clean the intake valves using methods such as walnut blasting or chemical cleaners.

Step 9: Sensor and Electrical Inspections

- Procedure: Check sensors such as the MAF, O2, and knock sensors for proper operation.

- Common Fixes: Replace any faulty sensors to ensure proper engine management and performance.

Step 10: Road Test

- Procedure: After performing the above checks and repairs, conduct a road test to ensure that the engine operates smoothly under various conditions.

- Common Fixes: If issues persist, further diagnostic work may be needed, possibly involving more specialized equipment or techniques.

When to Seek Help from a Professional Mechanic or Dealership

Complex Diagnostic Issues

- Diagnostic Trouble Codes (DTCs): If your Hyundai 2.5 Turbo engine is showing warning lights or error codes, a professional mechanic or dealership can provide a precise diagnosis using advanced diagnostic tools.

- Intermittent Problems: Issues like stalling, hesitation, or irregular performance that are not easily replicated may require expert analysis to pinpoint the underlying cause.

Specialized Equipment and Expertise

- Turbocharger Problems: Turbo systems are complex and can involve intricate components like wastegates and intercoolers. Dealerships have the specific tools and training to handle these systems effectively.

- Software Updates: Modern vehicles often require software updates to resolve issues, which can only be performed at a dealership.

Warranty and Recall Work

- Recalls and Service Bulletins: For any recall or service bulletin issues, visiting a dealership is necessary as they are authorized to perform these repairs at no cost to the owner.

- Warranty Claims: If your vehicle is under warranty, repairs related to engine problems must typically be handled by a dealership to comply with warranty terms.

Benefits of Getting Expert Assistance in Resolving Engine Problems

Accurate Diagnostics

- Expert Knowledge: Dealerships and certified mechanics have access to the latest training and information directly from Hyundai, which helps in accurately diagnosing and fixing the engine problems.

- Advanced Tools: Dealerships are equipped with Hyundai-specific tools that are often required for certain repairs or diagnostics, ensuring that the work is done correctly.

Quality of Repairs

- OEM Parts: Dealerships use Original Equipment Manufacturer (OEM) parts that are specifically designed for your vehicle, ensuring compatibility and reliability.

- Guaranteed Work: Most dealerships offer a warranty on the work performed, which provides an added layer of security for the repairs.

Convenience and Support

- Loaner Vehicles: Many dealerships provide loaner vehicles when your car needs to stay in the shop for an extended period, minimizing inconvenience.

- Customer Service: Dealerships often have dedicated customer service departments to handle any post-repair issues or concerns.

Long-Term Vehicle Health

- Preventive Maintenance: Regular servicing at a dealership helps in maintaining the vehicle according to Hyundai’s specifications, which can prolong the life of your engine and prevent future issues.