Wheel bearings can go bad due to several reasons:

- Normal wear and tear from regular use

- Poor installation practices

- Inadequate lubrication of the bearings

- Exposure to water and contaminants

These factors can lead to premature failure of the wheel bearings, resulting in potential safety hazards and the need for replacement.

Normal Wear and Tear

Like any other mechanical component, wheel bearings will naturally wear down over time due to regular use. You'll find that driving your vehicle inevitably subjects the wheel bearings to constant pressure and friction, which are the primary culprits behind their wear and tear. This isn't something you can avoid; it's simply a part of the life cycle of any car part.

As you rack up miles, the quality of the wheel bearings begins to decline. You're not doing anything wrong by driving your car – it's just the nature of mechanical parts to wear out. The materials that make up the wheel bearings, although being durable, will gradually degrade. This degradation leads to a decrease in performance, which you might notice as odd noises or a change in your vehicle's handling.

It's important to keep in mind that different driving conditions can accelerate this process. If you're frequently driving on rough or unpaved roads, the additional stress can cause the wheel bearings to wear out more quickly. Also, exposure to water and dirt can introduce contaminants that further reduce the lifespan of your wheel bearings.

Recognizing that normal wear and tear are inevitable helps you stay on top of maintenance. Keeping an eye out for the signs of worn bearings and addressing them promptly can save you from more significant issues down the line. Bear in mind, it's all part of keeping your vehicle in top shape. Just as you'd replace worn tires or brake pads, you'll need to replace your wheel bearings eventually. It's just part of the voyage of vehicle ownership.

Poor Installation Practices

Beyond normal wear and tear, improper installation can greatly shorten your wheel bearings' lifespan. It's essential you understand the pitfalls of poor installation practices to guarantee your vehicle's wheel bearings endure as long as possible.

Firstly, using incorrect tools or methods can wreak havoc on new bearings. For example, if you're hammering directly on the bearing to fit it into place, you're likely causing internal damage. Always use the right tools designed for bearing installation to avoid exerting excessive force. This can be as simple as a bearing press which ensures an even, damage-free fit.

Another common mistake is neglecting to clean the housing or spindle before installation. Even the smallest particles can cause abrasion or uneven wear, drastically reducing the bearing's service life. Make sure you clean these components thoroughly, removing all debris and corrosion before you install the new bearing.

Improper torque is also a significant issue. Too much torque can preload the bearing, leading to excessive heat and wear, while too little can cause play, leading to uneven wear and early failure. It's essential to follow the manufacturer's specifications for torque settings to avoid these issues.

Lastly, avoid rushing the installation process. It's tempting to cut corners when you're in a hurry, but taking your time to guarantee everything is done correctly can save you from premature bearing failure. Remember, patience during installation can extend the life of your wheel bearings significantly.

Inadequate Lubrication

After covering the significance of proper installation, it's essential to address how inadequate lubrication can further lead to wheel bearing failure. You mightn't think much about the lubrication in your vehicle's wheel bearings, but it plays a pivotal role in their longevity and performance. Without the right amount of high-quality lubricant, your wheel bearings can't do their job effectively.

Here's the deal: lubrication minimizes friction between the moving parts within the bearing assembly. This reduction in friction is important since it prevents excessive heat buildup, which can lead to premature bearing failure. When there's not enough lubricant, or if the lubricant has degraded over time and hasn't been replaced, the bearings will start to wear down at an accelerated pace. You'll soon find yourself facing a range of issues, from noisy operation to reduced vehicle handling and, ultimately, bearing failure.

Let's not forget, the lubricant serves as a barrier against contaminants like dirt, water, and other debris. These can enter the bearing assembly, especially if the seals are compromised. Without adequate lubrication, these contaminants have a much easier time causing damage.

Driving Conditions

Driving conditions greatly influence the lifespan and performance of your wheel bearings. When you're maneuvering through different terrains and environments, your vehicle's wheel bearings take the brunt of the impact. It's not just about the miles you cover, but how you're covering them. The conditions under which you drive can accelerate wear and tear on these critical components, potentially leading to premature failure if not properly managed.

Here are some specific driving conditions that can adversely affect your wheel bearings:

- Potholes and Rough Roads: Every time you hit a pothole or speed over rough terrain, it sends shockwaves through your vehicle's suspension system, right down to the wheel bearings. Over time, this can cause them to deteriorate faster than they normally would.

- Heavy Loads: If you're constantly hauling heavy loads or towing trailers, the additional weight increases the stress on your wheel bearings. This added pressure can lead to a decrease in bearing life.

- High-Speed Driving: Frequent high-speed driving puts extra strain on wheel bearings due to the increased forces exerted on them. This is especially true on highways where constant high speeds are maintained for extended periods.

- Frequent Starts and Stops: City driving, with its constant stopping and starting, can be tough on wheel bearings. The repetitive nature of acceleration and deceleration puts a lot of stress on the components, contributing to wear.

Comprehending how these conditions affect your wheel bearings can help you take preventive measures, like regular inspections and maintenance, to assure a longer lifespan for these critical parts.

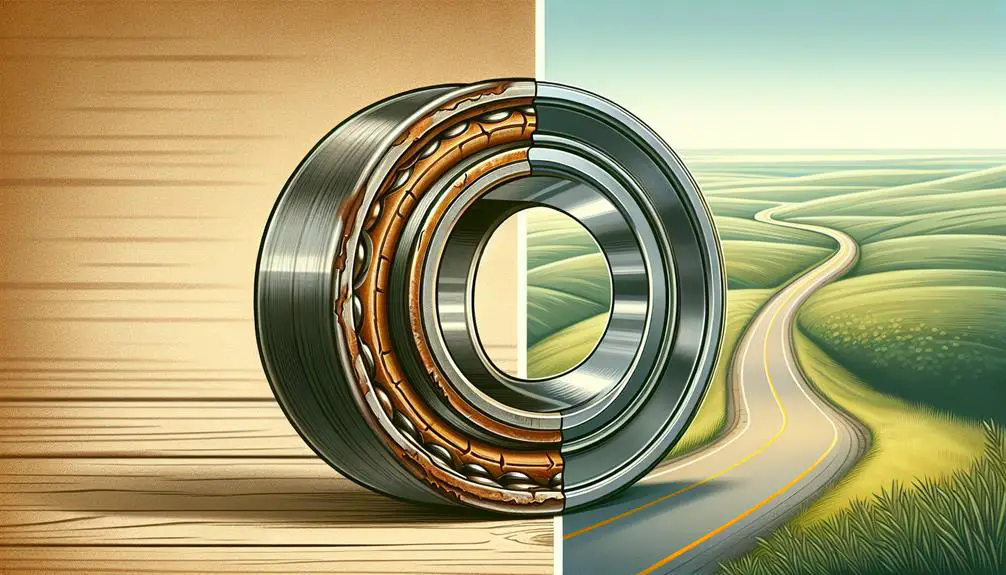

Water and Contaminant Damage

Water and contaminants infiltrating your wheel bearings can greatly shorten their lifespan. When you're driving through puddles or floods, water can seep into the wheel bearings. This isn't just important water—it's often mixed with road salt, especially in winter, leading to corrosion and rust. Equally, dust, dirt, and other particles can find their way into the bearings through damaged seals or during off-road adventures.

Once inside, these contaminants act like abrasives, wearing down the surfaces within the bearing assembly. This degradation isn't immediate, but over time, you'll start noticing symptoms like strange noises or a rough ride. It's essential to understand that even small amounts of water or dirt can cause significant damage. Water, for instance, doesn't just rust the bearings; it can also wash away the lubricant that keeps everything running smoothly. Without this lubrication, the metal components rub directly against each other, accelerating the wear and tear.

You might wonder how to prevent this. The solution lies in regular maintenance and inspections. Checking your wheel bearings for signs of damage or leaks can catch issues early, preventing water or contaminants from causing irreversible damage. If you live in an area with harsh winters or regularly drive on unpaved roads, consider asking your mechanic to check the condition of your wheel bearings more frequently.

Conclusion

To sum up, your wheel bearings can go bad for different reasons. Normal wear and tear, poor installation, and inadequate lubrication play significant roles.

Your driving conditions, along with exposure to water and contaminants, can further damage them. It's important to be mindful of these factors to guarantee your vehicle's safety and longevity.

Regular checks and maintenance can help prevent these issues, keeping you and your wheels smoothly rolling down the road.